In the world of modern transportation, fuel efficiency and vehicle maintenance are critical concerns for fleet managers and trucking companies. A significant yet often overlooked aspect of truck tire maintenance is the health of the tires. Tires play a crucial role in a vehicle’s overall performance, especially when it comes to fuel economy and tire longevity. This is where Tire Pressure Monitoring Systems (TPMS) come into play. TPMS technology provides real-time data on tire pressure, helping fleet managers optimize tire health, enhance fuel efficiency, and extend tire life. In this article, we’ll explore how TPMS monitors can improve fuel efficiency and increase the lifespan of truck tires.

What is TPMS?

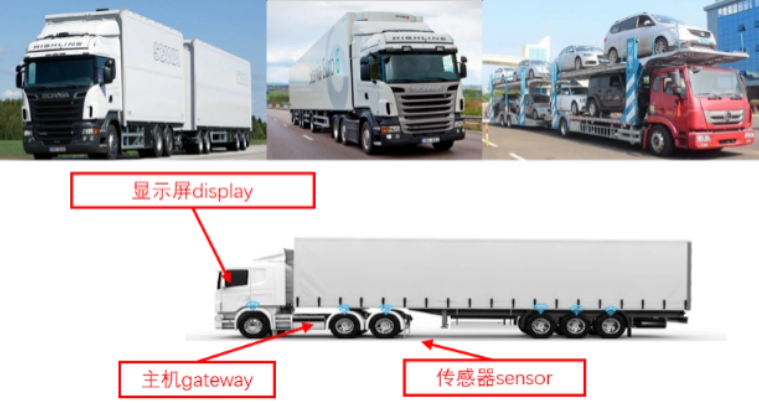

TPMS, or Tire Pressure Monitoring System, is a technology that continuously monitors the air pressure inside a vehicle’s tires. TPMS uses sensors installed inside or on the tire valve to measure tire pressure and transmit the data to a central system. If the pressure in any tire falls below a predefined threshold, the system alerts the driver or fleet manager. TPMS can be either direct or indirect:

- Direct TPMS: This type of system uses sensors inside each tire to measure air pressure directly and send this data to the vehicle’s central system.

- Indirect TPMS: This type of system doesn’t measure pressure directly but uses the vehicle’s ABS (Anti-lock Braking System) to monitor changes in wheel speed, which may indicate changes in tire pressure.

Direct TPMS is more common for heavy-duty trucks as it offers more precise, real-time data on tire condition.

How TPMS Improves Fuel Efficiency

Fuel efficiency is critical in the trucking industry. Fuel costs can account for a large portion of operational expenses, and even small improvements in fuel efficiency can translate into significant savings. Tire pressure is one of the primary factors that impact fuel consumption. Under-inflated tires are a common culprit behind poor fuel efficiency, and TPMS systems help address this issue in the following ways:

1. Preventing Excessive Rolling Resistance

When tires are under-inflated, they experience higher rolling resistance. Rolling resistance is the force required to keep a tire rolling, and it increases as tire pressure decreases. Higher rolling resistance means the engine has to work harder to move the truck, which directly reduces fuel efficiency. TPMS provides real-time pressure data, helping drivers and fleet managers spot under-inflated tires before they cause a noticeable decline in fuel efficiency.

By maintaining proper tire pressure, TPMS ensures that tires experience optimal rolling resistance, which improves fuel efficiency.

2. Optimizing Tire Performance

A TPMS system continuously monitors tire pressures and alerts drivers to any pressure imbalances. Correct tire pressure not only reduces rolling resistance but also helps tires perform better, leading to smoother driving. When tires are properly inflated, there’s less friction with the road, which decreases fuel consumption.

Moreover, driving with properly inflated tires ensures that the truck operates at peak performance, preventing the engine from working harder than necessary to overcome resistance. Over time, this contributes to consistent fuel savings.

3. Early Detection of Tire Issues

Under-inflation isn’t the only problem TPMS can detect. Over-inflated tires can also affect fuel efficiency by causing increased tire wear and impacting road contact, leading to less traction and inefficient fuel consumption. TPMS systems monitor tire pressure constantly, allowing fleet managers to identify potential problems, such as slow leaks or tire damage, that could affect fuel efficiency.

By addressing these issues promptly, truck drivers can ensure the vehicle remains fuel-efficient and that tires are operating within their optimal pressure range.

How TPMS Extends Truck Tire Life

The lifespan of truck tires is crucial for fleet operators. Replacing tires can be an expensive and time-consuming process, so extending their life is essential for reducing overall operational costs. TPMS plays a key role in preserving tire health and improving longevity in several ways:

1. Preventing Uneven Tire Wear

When tire pressures are not properly maintained, it can lead to uneven wear patterns across the tire surface. Under-inflated tires, for example, wear out faster on the edges, while over-inflated tires tend to wear more in the center. This uneven wear leads to a reduction in tire life and the need for premature replacements.

TPMS systems help fleet managers ensure that tires are inflated to the correct pressure, reducing the chances of uneven wear. As a result, tires last longer, and replacement costs are minimized.

2. Minimizing Heat Buildup

Tire pressure directly impacts the amount of heat generated by the tires. When tires are under-inflated, they flex more than they should, which creates additional friction and heat. Excess heat is one of the primary causes of tire degradation and can result in blowouts, tire failure, or a significant reduction in tire life.

By alerting drivers to low tire pressure early, TPMS helps minimize the risk of excessive heat buildup. Proper tire pressure ensures that tires operate at their optimal temperature, reducing the risk of premature aging and wear, thereby extending the overall lifespan of the tires.

3. Improving Tire Alignment and Balance

Maintaining correct tire pressure also ensures proper tire alignment and balance. Incorrect tire pressure can lead to misalignment, which causes tires to wear unevenly and more rapidly. TPMS helps keep tire pressure consistent, which in turn supports proper alignment and balance, leading to longer-lasting tires.

Moreover, tire alignment and balance issues can negatively impact fuel efficiency, so addressing these concerns with TPMS also contributes to both fuel savings and extended tire life.

TPMS Technology and Fleet Management

For fleet operators, TPMS is an invaluable tool. The ability to remotely monitor tire pressure in real time allows fleet managers to maintain more accurate oversight of their fleet’s performance. By having access to data on each tire’s pressure, they can schedule maintenance and repairs at the right time, avoiding unnecessary costs.

Moreover, fleet managers can use TPMS data to track tire health over time, making it easier to identify patterns and trends in tire wear. This enables proactive maintenance strategies, such as rotating tires and replacing those that are worn out before they affect performance.

Conclusion

TPMS technology offers a range of benefits that significantly improve both fuel efficiency and tire longevity. By maintaining optimal tire pressure, TPMS reduces rolling resistance, prevents uneven wear, and minimizes heat buildup, all of which contribute to better fuel economy. Furthermore, by detecting tire issues early, TPMS helps to extend the life of truck tires, reducing the need for frequent replacements.

For fleet operators, investing in TPMS technology is a smart move that can yield long-term savings, both in terms of fuel costs and tire replacement expenses. As the trucking industry continues to focus on sustainability and operational efficiency, TPMS will play an essential role in achieving these goals, making it a must-have for modern fleets.

Incorporating TPMS into your fleet management strategy can be a game changer—improving fuel efficiency, reducing operational costs, and enhancing overall tire performance.